Materials Test Lab Radiance: Deciphering Quality with Competence

Wiki Article

Advancing Innovation: The Important Function of Materials Testing in Numerous Industries

Advancements in innovation throughout different markets are driven by the vital role of products screening. In order to make certain efficiency, top quality, and security, products screening plays a crucial function in markets such as aerospace, vehicle, healthcare, and building. By subjecting materials to strenuous testing scientists, engineers and procedures have the ability to assess their properties, toughness, and dependability. In the aerospace industry, products screening assists in the development of light-weight and high-strength products that endure extreme conditions. In the automotive industry, products examining allows the development of much safer, extra fuel-efficient vehicles. Additionally, in health care and building, materials evaluating makes certain the use of secure and trusted materials, enhancing both person care and facilities. Eventually, products screening permits the advancement of innovation in different industries by offering the foundation for safety and security, quality, and efficiency.Importance of Materials Testing in Aerospace

Products screening plays a pivotal function in making certain the reliability and safety of aerospace components and frameworks with extensive examination and evaluation. In the aerospace industry, where the risks are high and the consequences of failing can be disastrous, the requirement for detailed and exact screening is paramount.Aerospace materials have to hold up against severe conditions such as high temperatures, pressure differentials, and resonances, while preserving their structural honesty. Materials screening permits designers to evaluate the efficiency and durability of these products under substitute operating problems. It helps recognize prospective weak points, issues, and failing modes, enabling for required design adjustments and renovations.

Additionally, products testing plays a crucial role in evaluating the viability of brand-new materials and making processes for aerospace applications. With improvements in technology and the introduction of unique materials, such as composites and superalloys, it is vital to evaluate their performance and compatibility with existing systems. Testing supplies valuable data on material buildings, behavior, and possible risks, allowing educated decision-making in the layout and option of products for aerospace applications.

Products Testing in the Automotive Industry

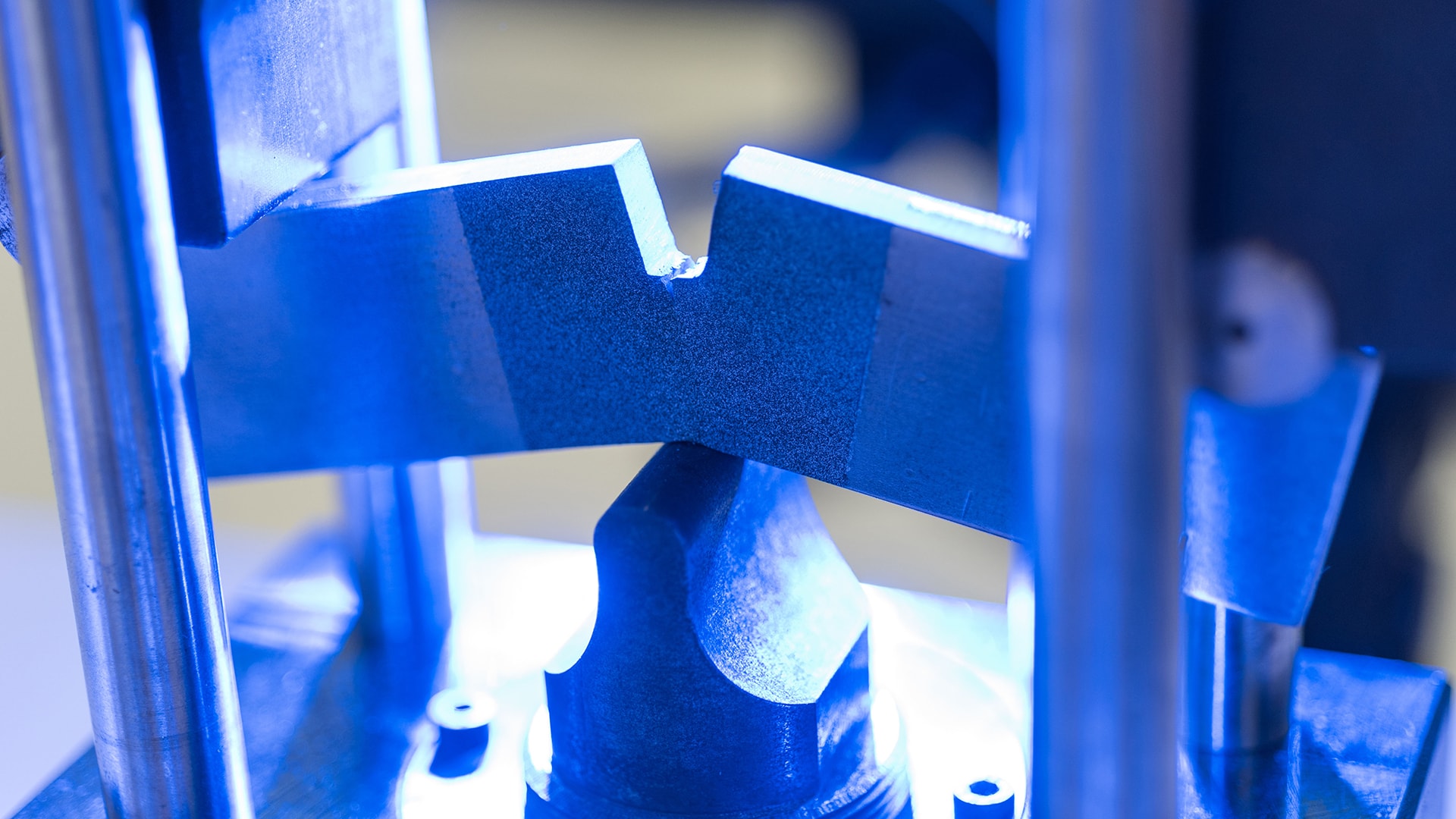

In the world of auto manufacturing, materials screening plays an important function in making certain ideal performance and safety of car components and structures. The auto sector needs products that can hold up against severe problems such as high temperature levels, harsh environments, and intense resonances. Strenuous screening is required to review the mechanical buildings and resilience of different products used in auto applications.Products testing in the automotive sector encompasses a variety of evaluations, consisting of tensile toughness, solidity, effect resistance, fatigue life, and corrosion resistance. These tests help producers choose one of the most ideal materials for various parts of the car, such as the engine, framework, body, and indoor elements.

One of the important facets of materials testing in the automobile industry is crashworthiness analysis. This involves subjecting automobile structures and security parts to substitute crash scenarios to evaluate their capability to dissipate and soak up impact power, therefore securing occupants throughout mishaps. By carrying out such examinations, producers can maximize the layout and products utilized to boost overall car safety.

In addition, products screening additionally plays a critical function in advancing auto modern technologies. With the raising need for electrical automobiles (EVs), materials testing aids ensure the performance and dependability of battery systems, electrical elements, and lightweight products used to maximize variety and performance.

Ensuring Safety And Security and Quality in Healthcare With Materials Testing

Guaranteeing security and quality in health care depends greatly on extensive products checking treatments. Using appropriate materials in medical gadgets, devices, and pharmaceutical items is critical to stop harm to clients and guarantee the efficiency of therapies. Materials testing site link plays an essential function in the health care industry by examining the physical, chemical, and biological homes of products used in medical applications.One key element of materials screening in healthcare is the assessment of biocompatibility. Medical tools and implants have to be suitable with the body to reduce the risk of adverse reactions, such as tissue, swelling, or infection being rejected. Evaluating techniques, such as cytotoxicity testing, sensitization testing, and implantation studies, aid establish the biocompatibility of materials.

Another essential location of materials screening in healthcare is the analysis of pharmaceutical products. materials test lab. Testing guarantees that medications are safe, reliable, and totally free from impurities. This consists of analyzing the stability and integrity of medicine formulations, analyzing the launch of energetic ingredients, and recognizing potential pollutants or destruction products

Moreover, products screening is vital in validating the performance and longevity of clinical equipment. Testing treatments assess the mechanical stamina, resistance to tear and put on, and integrity of tools, such as syringes, catheters, and surgical tools. This makes certain that healthcare specialists can count on these devices during crucial treatments, lessening the threat of failing or malfunction.

Enhancing Resilience and Performance in Building With Materials Testing

To guarantee enhanced sturdiness and efficiency in building, materials testing plays an essential duty by evaluating the structural stability and quality of structure materials. Construction projects call for materials that can hold up against different environmental conditions, tons, and stress and anxieties, and products testing aids in selecting one of the most suitable materials for the task.Products testing in construction includes subjecting building materials to a variety of examinations to identify their durability, performance, and toughness. These examinations include examining the compressive toughness of concrete, the tensile strength of steel supports, the resistance to rust, and the thermal homes of insulation products. By carrying out these tests, home builders and designers can make sure that the materials used in building and construction fulfill the called for requirements and specifications.

One of the major advantages of materials testing in building is that it aids identify any possible weaknesses or flaws in the structure products before they are utilized in the construction procedure. By identifying these issues at an early stage, needed changes can be made to make certain the architectural integrity and long life of the building.

Furthermore, materials testing likewise plays an essential duty in quality assurance during construction. By regularly evaluating the materials throughout the construction process, contractors can confirm that the products being used meet the needed specs and efficiency requirements. This ensures that the last framework will be secure, sturdy, and able to hold up against the desired lots and anxieties.

Pressing the Borders of Innovation: Products Testing in Various Industries

Materials testing plays a crucial function in driving technology and pressing the boundaries of excellence across different industries. By subjecting products to rigorous screening, scientists and engineers gain beneficial understandings into their residential properties and actions, enabling them to create enhanced and brand-new products and procedures. In the automotive market, as an example, materials screening aids boost car safety and security and performance by assessing the stamina, toughness, and crashworthiness of various elements. This enables producers to make and produce much safer and more reliable cars. materials test lab.In the aerospace industry, materials testing is important for making sure the integrity and efficiency of airplane frameworks and elements. Via comprehensive screening, designers can determine materials that can hold up against the rough problems of flight and fulfill strict safety criteria. This allows for the growth of lighter, a lot more fuel-efficient airplane that can hold up against severe temperatures, pressures, and resonances.

In the medical you can find out more field, products screening is crucial for the advancement of ingenious clinical devices and implants. By examining the biocompatibility, toughness, and toughness of materials, scientists can make sure that these items are risk-free and reliable for use in the human body. This allows innovations in areas such as orthopedics, cardiology, and dental care, causing improved individual outcomes and lifestyle.

In the energy sector, products testing plays a critical role in progressing eco-friendly power modern technologies. By subjecting materials to severe problems, researchers can recognize products with enhanced performance and sturdiness for usage in solar panels, wind turbines, and energy storage space systems. This drives advancement in the advancement of more sustainable and efficient energy services.

Conclusion

In conclusion, products screening plays a critical duty in different industries consisting of aerospace, vehicle, medical care, and building and construction. It makes sure security, quality, resilience, and efficiency of products used in these markets.In the aerospace market, products testing aids in the development of lightweight and high-strength products that hold up against extreme conditions. In healthcare and construction, materials testing makes sure the use of secure and reputable materials, boosting both person care and framework.Additionally, materials testing plays a vital role in analyzing the suitability of new products and making processes for aerospace applications. Evaluating gives important data on product homes, actions, and potential dangers, enabling informed decision-making in the layout and selection of materials for aerospace applications.

By on a regular basis evaluating the materials throughout the building and construction process, home builders can verify that click here for more the materials being utilized satisfy the required specifications and performance requirements.

Report this wiki page